The challenge goes on…

Nathan Mayer, our engineer, takes us on our latest additive manufacturing journey…

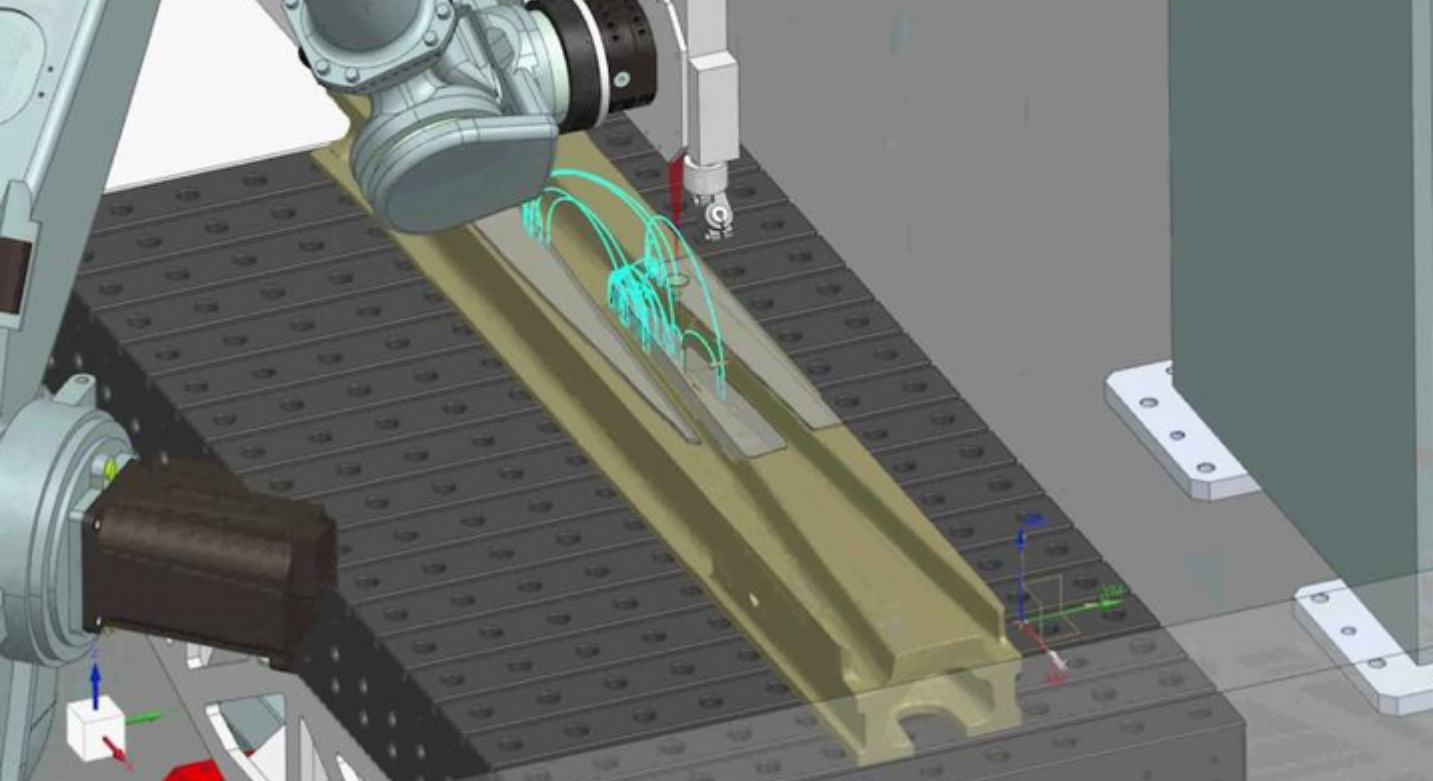

- It’s time for simulation!

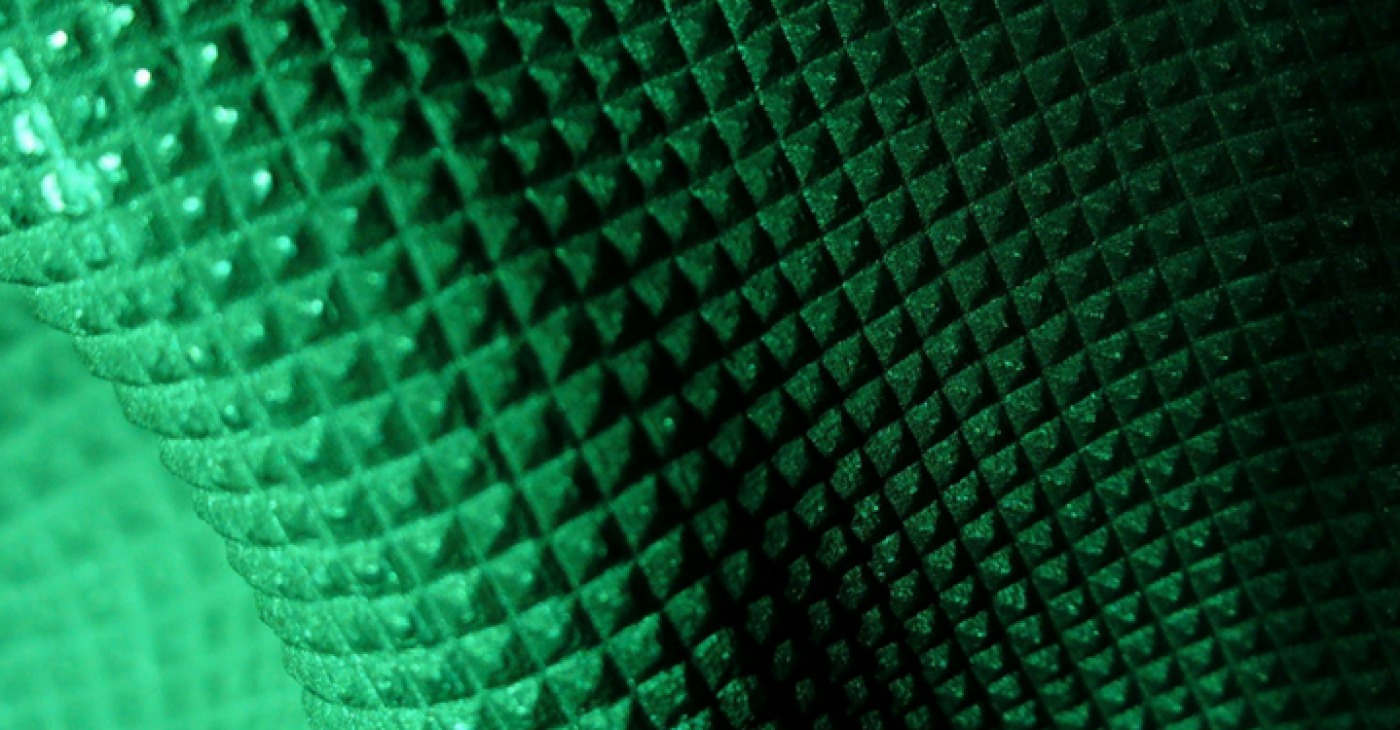

“The CAM part will be simplified due to several advantages of our WLAM process:

- Close to the final dimensions

- High deposition rate possible ➝ beyond 600cc/h

- Low dilution and manageable heat input

- Good mechanical characteristics

Exaggerating a bit, with the right deposition parameters, it will be like generating a path for a 3D printer. Once the building strategies are selected, the parameters filed and the trajectories generated, it’s time to apply some rules to our robots and simulate the operation to avoid any singular point or collision. The part is long (approximatively 2 meters) and the volumes to build are long too, so I generated the toolpath to have the longest deposition tracks and few “off-moves”.

Parameters and toolpath trajectories verified, I can post process my robot program and go back from the numerical world. Rail must now be installed on the machine and repaired!”

>> https://www.youtube.com/watch?v=EOu4dzMt2co

Keep going!

Stay tuned for the next phase…